High Speed Handling

Optimal handling and transfer systems can be planned for all glassware by suitable combination based on anthropomorphic systems.

Handling Robots, Tip Over and Conveyors:

The possible applications of modern transfer robots are many in glass production. In addition to removing items from the press, reliable positioning between different production sections is always required.

OToday in small glassworks the production is transferred manually to the annealing Lehr. Unfortunately, due to small batch sizes, fully automatic production is not possible in many cases.

This problem is solved with a system based on a conventional robot. With a mechanical gripper or vacuum head, this robot picks up the articles arriving on a conveyor belt, this lifts them off the conveyor belt, and in the corresponding position transfers them to another machine or onto the Annealing Lehr belt.

Picking Unit and Handling Robot

The picking device is used within the automatic process system two/three times.

The first for unloading the forming machines, the second for loading the rim polishing or Burn Off machine and the third for picking up the product from the product holders and depositing it on the conveyor belt.

The first take-out is placed between the press and the fire polisher. A similar device is located between the fire polisher and the conveyor of the subsequent transport system, or in the case of blown tableware production it is located between the Burn Off and the conveyor.

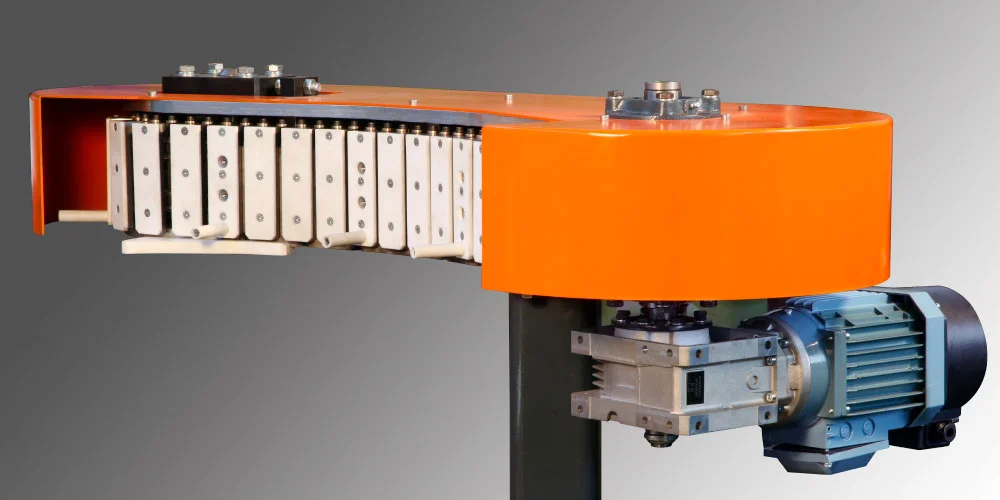

Conveyors

The conveyor belt is running ensuring that normal traffic in the glass factory is not disturbed.

Low risk of breakage

The glass is transferred from the glazier's workplace to the annealing Lehr in one go, with speed and in the shortest possible time, thus guaranteeing a low risk of breakage.

exceptionally smooth transport surface

Customers need a durable, flat and exceptionally smooth conveying surface for the rapid and synchronized conveying of fragile products. Lack of lubrication and drastic temperature changes from the hot-end can compromise production performance.

specific options

Even if it is a conveyor, specific options must be installed on it which allow to achieve quality productions, such as muffles, burners, transfer plates in special materials so as not to break the glass.